Initial situation:

Within the tank farm of a refinery, a kerosene damage occurred, which was to be remedied via three remediation wells.

The requirements for the remediation system included among others a flow rate of max. 100 m³/h at an operating pressure of up to 5 bar.

At the same time, the concentration of hydrocarbons had to be permanently reduced in accordance with the discharge specifications:

BTXE: <50 µg/L

Benzene: <10 µg/L

Trimethylbenzene: <50 µg/L

Naphthalene: <2 µg/L

After the start of the remediation plant, difficulties arose due to changing influent levels.

Increasing iron levels resulted in iron hydroxide sludge that settled on the activated carbon of the filters.

Clogging of the activated carbon filters resulted in a pressure increase and reduced flow of approximately 25 m³/h.

Solution:

- BROCKHAUS SWS for wastewater treatment.

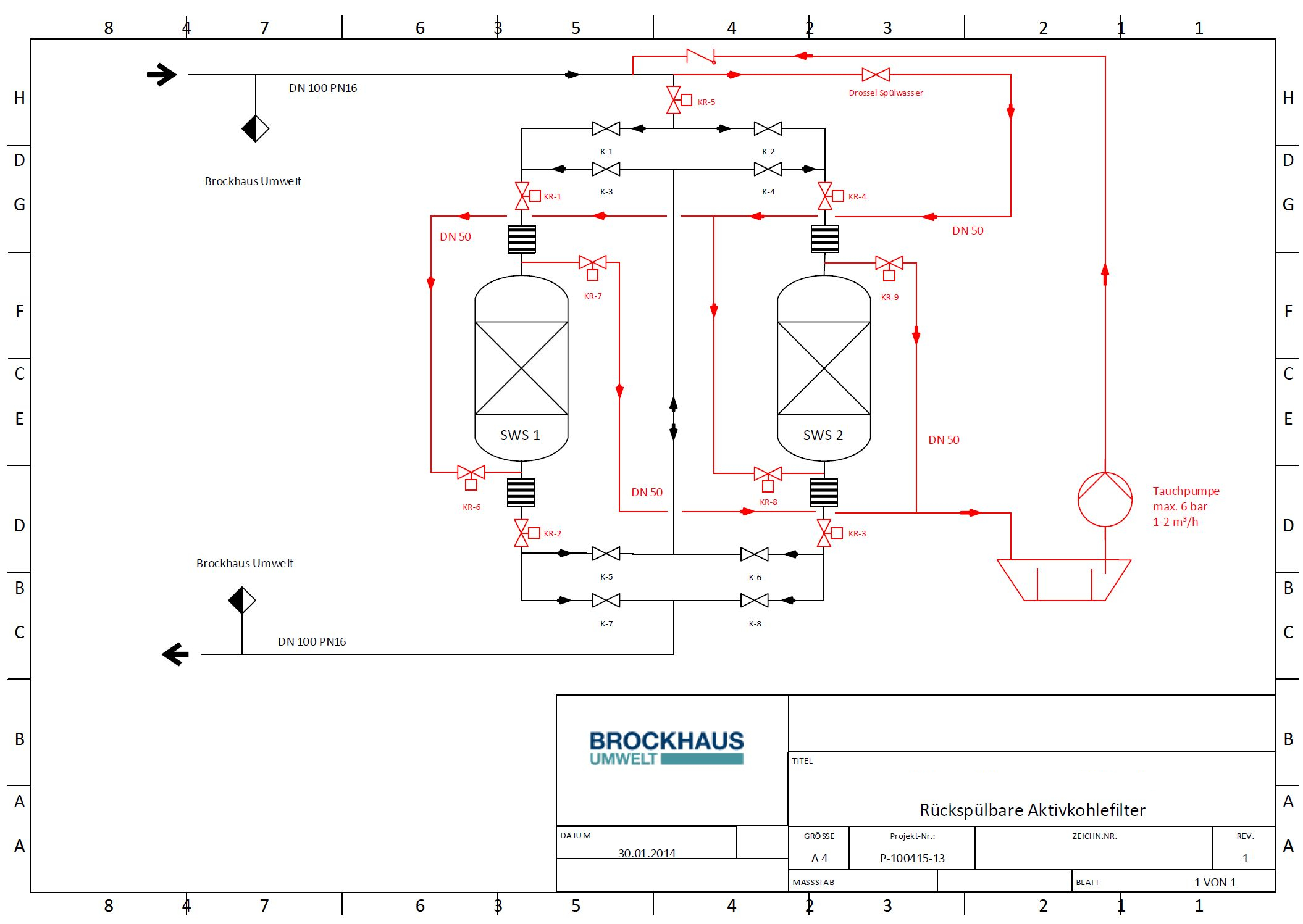

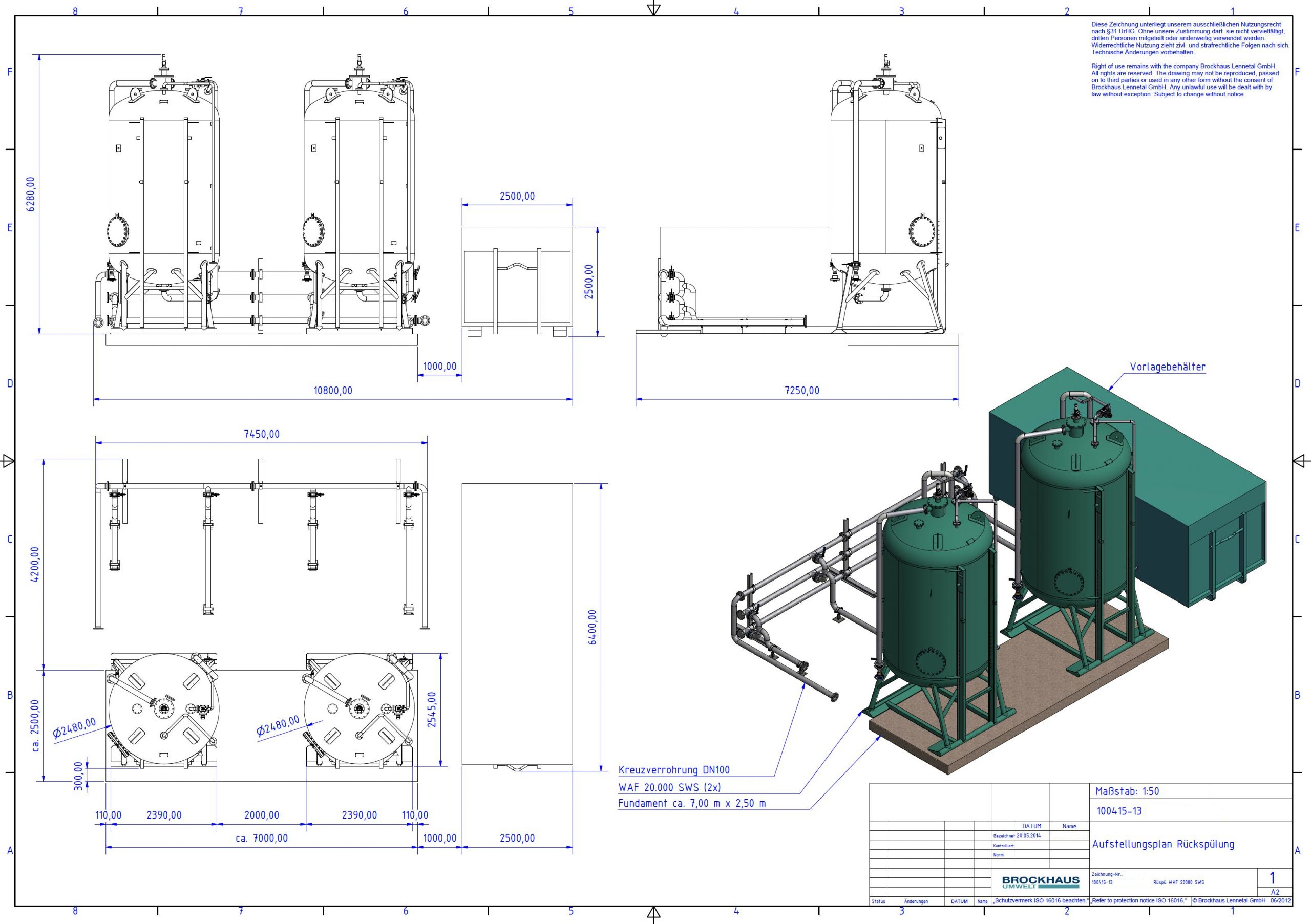

- 2 x WAF 20.000 in parallel connection, back flushable and pressure resistant up to 6 bar

- BROCKHAUS Monitoring for monitoring and control of the plant

- Control of the backwash unit

- Monitoring of the operating parameters

- Receiver tank

- For backflushing of the activated carbon filters

- Cross piping for separate control of the activated carbon filters and the receiver tank

- Other BROCKHAUS equipment:

- Piping, hoses, and other equipment

Result:

New cross piping and an additional receiver tank were installed to meet the new challenge that arose after the start.

With the new equipment and the appropriate control system, the filters could now be backflushed.

This allowed the iron hydroxide sludge from the activated carbon filter to be returned to the receiver tank, thus preventing clogging.

Backflushing of the filters now takes place three times a day and is additionally supported by differential pressure measurement.

These measures made it possible to implement a stable process that has now met the discharge specifications since 2014.