In the modern automotive industry, efficiency is the determining factor. Brockhaus High Performance Steel, or BHS for short, is the answer in terms of material efficiency. It combines high component strength with high formability and a simultaneous weight and cost advantage.

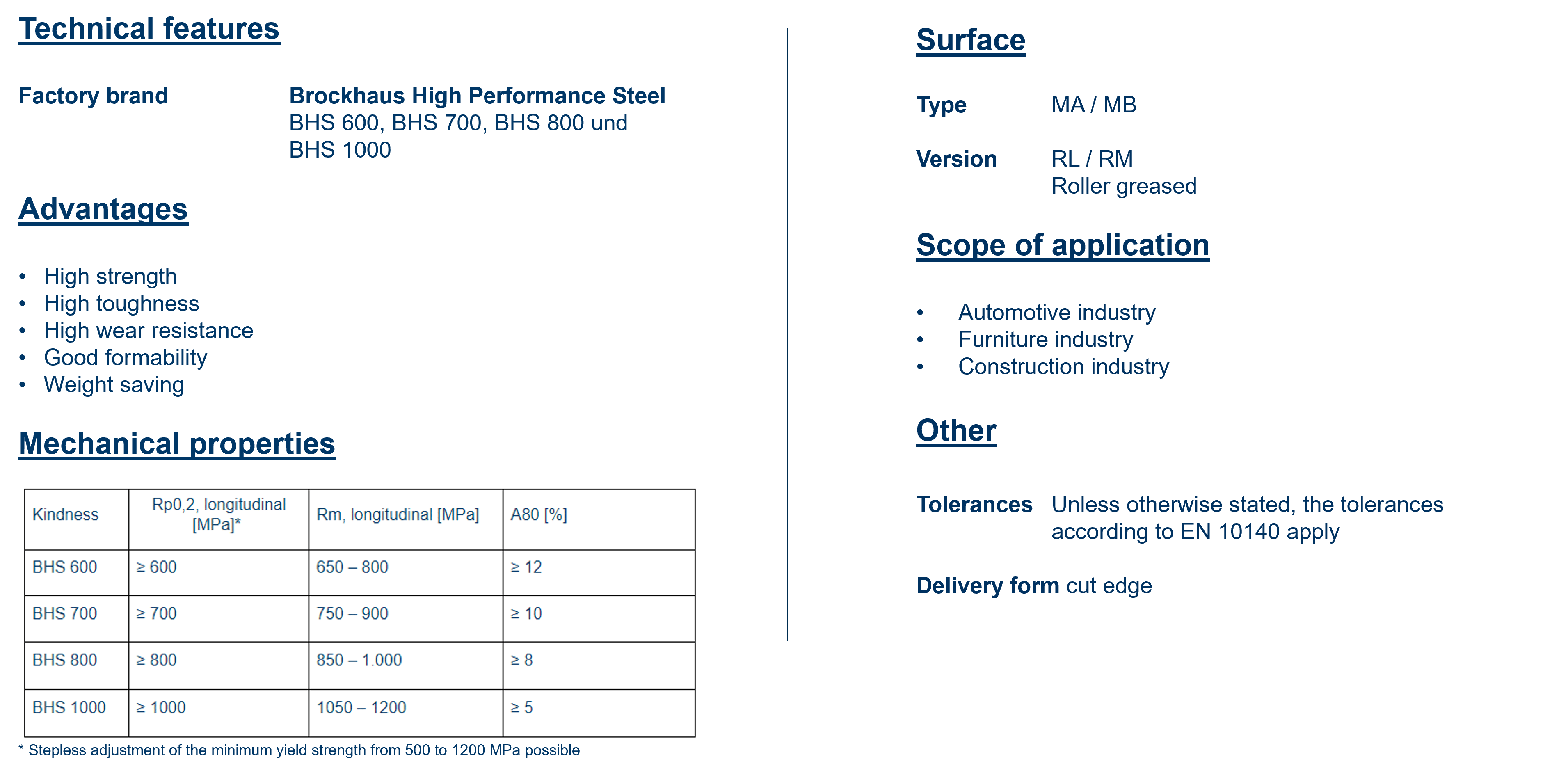

Based on micro-alloyed fine-grain steels, the special mill grade “BHS” is characterised by high strength and thus high wear resistance. In addition, there is no need for subsequent heat treatment to adjust the required service properties after forming, which leads to distortion and thus to a strong impairment of the shape and position tolerances. Despite their very high strength and a yield strength ratio (Rp0.2/Rm) of up to ≥ 95 %, the BHS factory grades still ensure sufficient formability for a wide range of forming operations. Due to the combination of high strength and high toughness, a significant weight saving of up to 50 % can be achieved on the end product.

This efficient material for the automotive industry is used in all areas of the car where extreme loads have to be absorbed, such as in seat or airbag systems, but also in the furniture industry for hinges or in the construction industry for window profiles.