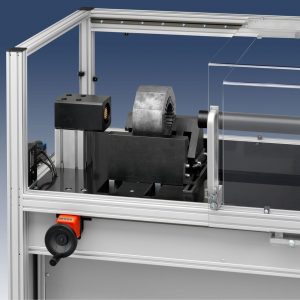

- Thickness and profile measuring system for use in production lines

- For cold and hot rolled strips and sheets

- Measuring procedure free of contact

- High accuracy and short response times

- Depending on the system one- or two-sided measurement is possible

Operating principle

High-performance electromagnetic measuring process for the quality control of cold and hot rolled strips and sheets.

Fast evaluation of measuring values and high accuracy. For use in extreme conditions, measurements unaffected by emulsions, lubricants, dust, etc.

Measuring sensor with exciting coil and measuring coil. Together with the material to be measured, they form a transformer whereby the exciting coil is the primary and the measuring coil the secondary winding. The electric current is provided to the primary winding by means of a high-performance triangular alternating current; the induced voltage on the secondary winding is standard for the thickness of the material to be measured.

In accordance with the prescribed nominal thickness, the amplitude and frequency of the primary circuit are regulated in such a way that the material is in high polarization.

Measurement and evaluation via a real-time microprocessor system. Integration of the acquired data into QM systems.

Technical data

| Repeatability accuracy: | better than 0.2 % |

| Measuring accuracy: | better than 0.5 % |

| Minimum strip width: | 90 mm |

| Strip thickness: | 0.01 – 3 mm |

| Power supply: | 3 x 400 V AC, 50 Hz (standard) |

Related Measuring Instruments

More Measuring Insturments