- Detection of holes with a dimension of > 0.5 mm

- Detection of strip width with an accuracy of +/- 1 mm

- Detection of cracked edges

- Display of actual strip statistics

Operating principle

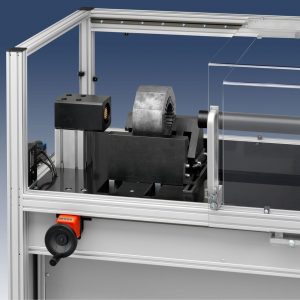

Inline measuring instrument for quality control in the production and processing of rolled steel (coils, rings).

The optical measuring instrument checks the width of the inserted material and tests the material for holes and cracked edges.

The width measurement and hole detection instrument works with various widths and is integrated as an inline measuring instrument in continuous production and inspection lines. It consists of the following components: 19? cabinet with measuring unit and colour monitor, high resolution line camera and background illumination. High-performance software allows permanent display and evaluation of the measuring results in real time. The software enables exact localization of faults over the whole width of the strip. Additionally any deviations of the material width from the nominal value are reported and registered.

The construction and operating mode of this optical measuring instrument are designed for use with other strip materials.

Technical data

| Detection of holes: | > 0,5 mm |

| Width measurement: | +/- 1 mm |

| Width of strip: | < 1300 mm |

| Thickness of strip: | < 1mm |

| Measuring optics: | line camera |

| Line speed: | max. 200 m/min |

| Measurement: | digital recording |

| Display: | 17? monitor |

| Software package: | Windows 98/2000/NT compatible |

Related Measuring Instruments

More Measuring Insturments