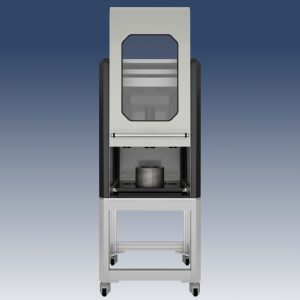

- BST-SA Semi-automatic version, suitable for:

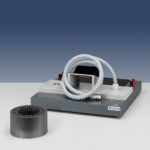

Minimum ID of measured stator: 95mm

Maximum OD of measured stator: 300mm

Maximum height of measured stator: 280mm

Maximum weight of measured stator: 60kg - Non-destructive testing of the magnetic properties of stators

- Quality control of stators in seconds

- Time-consuming manual preparation of samples is no longer necessary

Operating principle

The testing station consists of a testing cage made from aluminium profiles. The front section is fitted with a safety light shield. This guarantees very quick operating processes. The stator package is fixed via a horizontal drill hole into a small prism. When the area of the safety light barrier is clear the testing process can be started by using the start button. Then a u-shaped bracket with 64 windings moves into the stator and makes contact with the opposite side. The measurement is started with a start signal. If the measuring result is positive (the stator corresponds to the norm) the u-shaped bracket recedes and the measuring sample can be removed. If the result is negative (the stator does not meet the norm) the u-shaped bracket remains closed – a lamp lights up – and can only be released by activating a switch manually.

Measuring categories

- Specific hysteresis loss [W/kg]

- Maximum polarisation [T]

- Effective polarisation [T]

- Maximum field strength [A/m]

- Effective field strength [A/m]

- Remanence [T]

- Coercive field strength [A/m

- Permeability

- Spezific apparent output [VA/kg]

- AC hysteresis curve

| Technical data: | Stator Tester BST-SA |

| Selectable measuring frequencies: | DC, AC 3 Hz – 20 kHz |

| Selectable field strength: | up to 8.500 A/m |

| Polarization: | 0,001 T up to 2 T |

| Repeatiability: | better 1 % ( ± 1digit) |

| Comparability of measuring results: | according to IEC 60404-3 |

| Maximum current: | ± 52 A |

| Maximum voltage: | ± 100 V |

| Winding configurations (primary/secondary) | 48/4, 8/4, 4/4 |

Further Stator Tester sensors