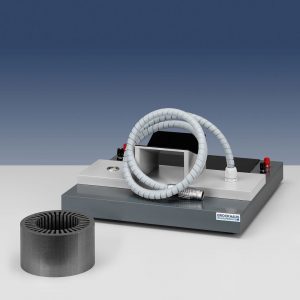

- Double yoke measuring coil system

- For the quality control of punched parts and narrow slit strips

- Suitable for all geometries and small material dimensions

- Designed in accordance with IEC 60404-3

- Optimal sequencing of coils

For measuring the magnetic properties (hysteresis loss etc.) of punched parts and narrow slit strips of oriented or non-oriented electrical steel. The material dimensions of an available and reproducible measurable sample can be as small as 8 mm x 3 mm because of the very favourable configuration of the yoke and coils. The C 510 measuring sensor covers a wide range of measuring requirements for punched parts and narrow slit strips. In addition, as a result of the very small measuring area, it enables a highly reliable inspection of material edges after cutting and punching.

Technical data

| Construction: | double-yoke with exciting and measuring coil |

| Pole area: | 26 x 25 mm |

| Field strength: | 5.000 A/m* max. |

| Polarization: | 0,001 T to 2 T** |

| Sample dimensions: | min. 8 x 3 x 0.2 mm (LxWxH) |

| Sample thickness: | max. 1.1 mm |

* Depending on the electrical steel measuring instrument selected

** Depending on the quality of the electrical steel being tested

Further sensors