- Determination of the magnetic properties of electrical steel and other soft magnetic materials

- Free configuring with specific measuring coil systems

- Parallel connection of up to 12 measuring coil systems

- Fully digitalized data documentation

- Measuring coil systems and evaluation according to IEC 69404 ff and ISO ASTM for measurement with Epstein frame and sheet measuring coil

- Versatile

- Easy to operate

- Automatic coil changeover for convenient operation

- Module for measurement of rings, ring strip cores, stacked laminations, etc.

- BROCKHAUS® MPG Expert software for measurement, presentation and integration into QM systems

Operating principle of MPG 100

In a measuring coil a material sample is exposed to a defined magnetic field and magnetic flux is created in the steel sheet. The electric current required is supplied by a power amplifier. The current is measured by means of a temperature-stable, induction-free precision resistor (shunt) or via field coils.

Determination of the polarization by measurement of the induced voltage, and then conversion and integration by means of a 16-bit processor. Parallel recording of the H and J sizes with separate recording systems guarantees absolutely simultaneous measurement. Faults in measurement caused by phase displacement are thereby ruled out. From the differentiated and integrated parameters the processor system can calculate all the above-mentioned values. There are no sources of faults such as analogue multipliers and integrators.

Measurement is by means of sinusoidal polarization. By using a control algorithm the secondary voltage can be checked and controlled sinusoidally. The nominal voltage is supplied by a highly stable, quartz-controlled digital sinus generator. Amplitude and frequency are set by the processor unit according to the sample data entered (weight, density, desired frequency, nominal polarization etc.).

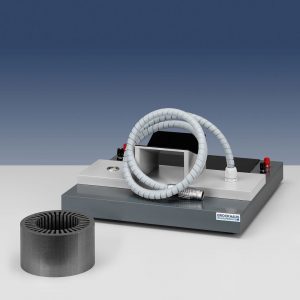

Measuring coil systems

- Epstein frame for frequencies of 50 Hz / 60 Hz according to IEC 60404-2

- Epstein frame for frequencies of 400 Hz according to IEC 60404-2

- C 510 measuring coil for punched parts, cuts and strip

- Single-strip measuring sensor for Epstein strips, comparable to IEC 60404 -3

- Single-sheet tester according to IEC 60404-8-7 (500 x 500 mm)

- Module for rings, transformer cores and stators

- Custom-made Epstein frames, single-sheet and single-strip measuring coils

Operation, Measurement and Evaluation

BROCKHAUS® MPG Expert software for simple operation of the instruments enables completely free parametering and structuring of the measuring processes under Windows.

Technical Data

| Title: | Electrical Steel Tester MPG 100 |

| Repeatability: | 0,2 % |

| Comparability of the measured results: | according to IEC 60404-ff. |

| Setting accuracy of the nominal value: | according to IEC 60404-ff. |

| Maximum current: | ± 40 A |

| Maximum voltage: | ± 110 V |

| Coil connectors: | 3 to 12 coils parallel |

| Operating mode: | PC / software |

| Model: | table or cabinet version |

| Measuring frequency: | 3 Hz – 10 kHz (optional DC), DC with adjustable rise time for primary signals and flux alteration control dΦ/dt |

| Power supply: | 3 x 220 – 440 V AC, neutral, PE |

Further sensors