Control the magnetic properties during your production with BROCKHAUS MEASUREMENTS technology

Why is stator testing essential?

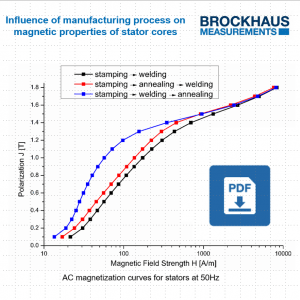

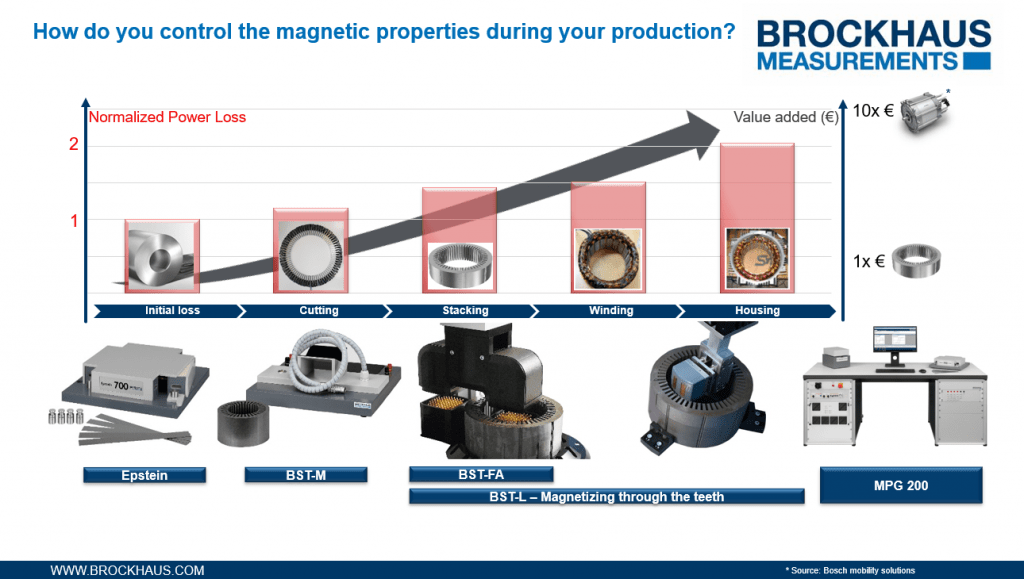

To meet the growing efficiency requirements of future electric motors, engineers worldwide are involved in optimizing every component of electric motors. Stator laminations made of special electrical steel have proven to be one of the critical parts that influence the performance of electric machines and the range of electric cars. Differences between the initial and postproduction magnetic properties of stator laminations are considered as one of the main sources of discrepancy between the expected and actual electric motor performances at the end-of-line-test. BROCKHAUS case studies show that the power loss can certainly double from “coil to stator”. Residual stress from cutting, stacking, and housing have significant impact on magnetics, which in the end lead to an increase in power loss and a deterioration in permeability.

How to control the magnetic properties?

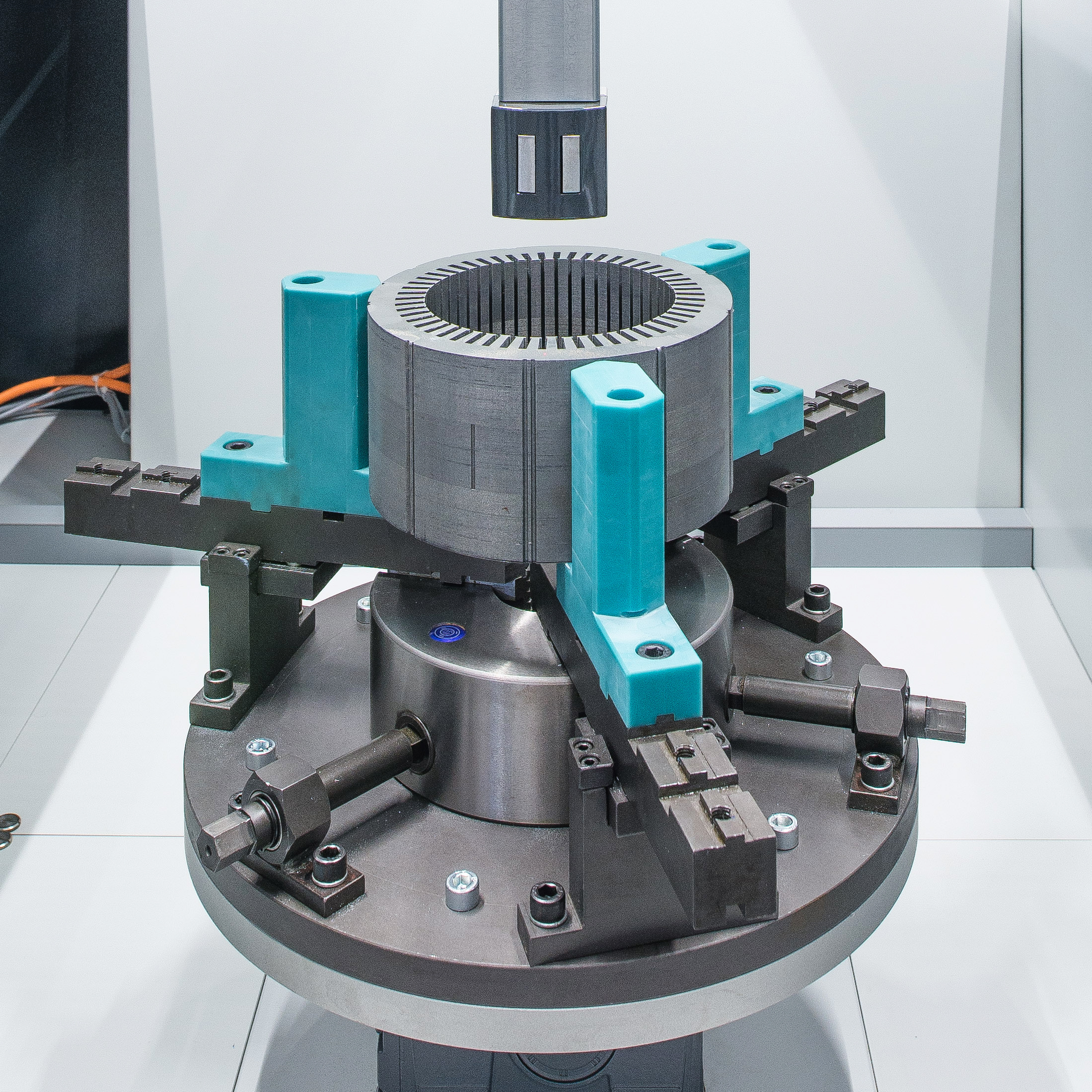

Over many years of exchange with research and industry, BROCKHAUS MEASUREMENTS has developed reliable and efficient testing technology to characterize the magnetic properties after different stages of manufacturing.

The BROCKHAUS Stator Tester Series includes:

Be sure of perfect results

- Test 100% of your stators inline within seconds

- Ensure consistently high quality of your stators

- Use your own limits regarding magnetic properties as a risk indicator to allow predictive maintenance

- Create internal data for Statistical Process Control (SPC) and determine your process capability acc. to IATF 16949 9.1.1.1

- Allow your customer maximum traceability to every stator

- Avoid claims and follow-up costs due to insufficient magnetic properties

- Increase customer loyalty through innovative quality standards with certified stators measured by state-of-the-art BROCKHAUS equipment