- Observe the stator quality at different manufacturing processes

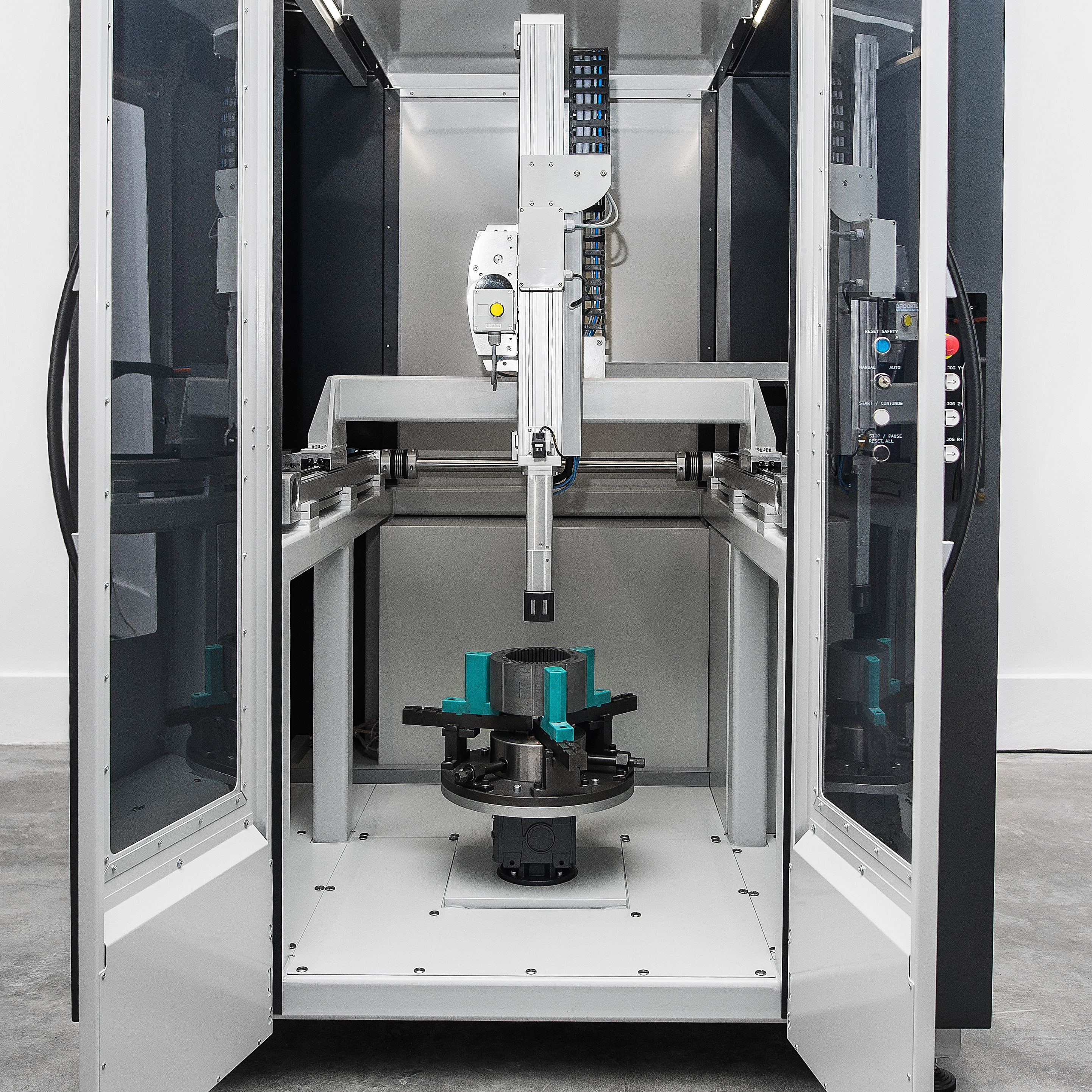

- Scanning system for positioning of the sensor head in pre-defined locations

- Rotating table with stator holding fixture

- Relative magnetic properties of the tested stator segments

- High repetitive accuracy

- BROCKHAUS® MPG Expert software for measurement, presentation and integration into QM systems

Operating principle

Automated measurement system comprising custom designed magnetic sensors integrated with XZ positioning system for comprehensive testing the magnetic properties of stator cores with focus on stator teeth and back iron analysis.

The BST-L system can be used for measurements of different stator segments comprising teeth and sections of back iron. The main components of BST-L system include:

• XZ scanning system for positioning of the sensor head in pre-defined locations

• Rotating table with stator holding fixture for setting different angular positions of sensor head within the stator core

• Customised sensor head including magnetic yoke and set of excitation and sensing windings

• Customised sensor head gripper integrated with XZ scanning system

• Cable for connecting with MPG200 magnetising unit

• Software package for control of automated testing sequence including stator and sensor head positioning, as well as measurement procedure

The BST-L system is integrated with the MPG200 magnetisation unit. Measurement parameters, such as frequency, shape (sinusoidal or/and arbitrary waveforms) and amplitude of polarization are specified by the user. The measurement output data includes information on the magnetic properties of the complete magnetised circuit, i.e. sensor head + teeth + back iron.

As the magnetic characteristic of the sensor head is known from prior yoke characterisation, it is possible to extract the relative properties of the tested stator segments.

These relative properties, e.g. power loss, can be used for comparative analysis of different segments within individual stator, as well as for comparison of stators after different manufacturing processes, such as: lamination cutting, stacking, winding, housing.

Technical Data

| System: | Stator Tester BST-L |

| Measuring frequencies: | 3 Hz to 20 kHz |

| Field strength | selectable 1 A/m up to 30000 A/m |

| Polarization: | 20 mT up to 2 T |

| Adjustment precision: | better than 0.2% |

| Repeatability: | better than 0.3% |

| Max workspace: | X direction: 200mm (corresponding to stator ID) Z direction: 300mm (corresponding to stator height) |

| X and Z drive: | Velocity: 0.1 m/s Acceleration: 1m/s2 Precision class: 0.1 mm |

| Rotating table: | Rotation precision: 0.1° Rotational speed: 30°/s |

| Power supply: | 3 x 400 V AC, neutral, PE |

Further Stator Tester sensors